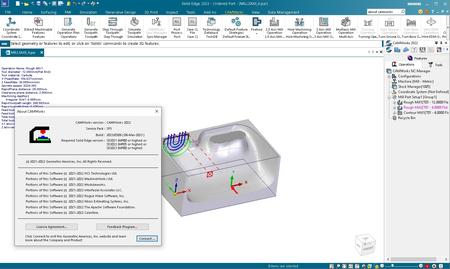

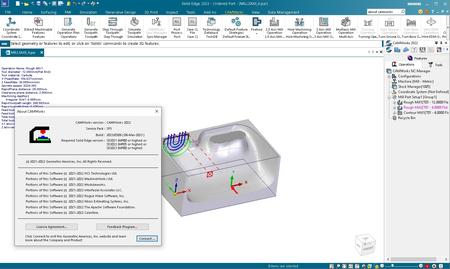

CAMWorks 2022 SP3 for Solid Edge (x64)

Author: crackserialsoftware on 1-05-2023, 09:09, Views: 98

Free Download CAMWorks 2022 SP3 for Solid Edge | 1.9 GbProduct:

Free Download CAMWorks 2022 SP3 for Solid Edge | 1.9 GbProduct:CAMWorks

Version:2022 SP3 (build 2023/0306)

Supported Architectures:x64

Website Home Page :www.camworks.com

Languages Supported:multilanguage

System Requirements:Windows *

Size:1.9 Gb

Languages Supported: 中文 Simplified, 中文 Traditional, Français, Deutsch, Italiano,

日本語, Polski, Português-Brazilian, Русский, Español, Türkçe, 한국어, ČeštinaThe GeometricPLM development team is pleased to announce the availability of CAMWorks 2022 SP3 (build 2023/0306) is an intuitive, feature-based CAM software that helps to increase productivity using best-in-class technologies and adaptable automation tools to maximize CNC machining efficiency.

CAMWorks constantly updates its software to satisfy the requirements of the manufacturing industry, as well as offering features to assist manufacturers through its software.

What's New in CAMWorks for Solid Edge 2022 SP3 (build 2023/0306)

1. CWR-2079 CSR-21526 Toolpath When the 3 Axis Mill Toolpath generation method is set to 'Advanced', the toolpath generated for 'Flat Area' operation is unable to restrict itself to the top flat surface of the part. This issue is observed when the Automatic Contain Area's tool condition is set to 'Past'.

2. CW-117429 CW-115824 CSR-21626 CSR-20657 Toolpath For the specific Mill part, if the Gouge Check option is unchecked, then the lead in/lead out for the Rest Machining Contour Mill toolpath gets applied in the incorrect direction resulting in gouging of the part. If the Gouge Check option is checked, then the toolpath fails to generate.

3. CW-117311 CSR-21585 UIF In Turn/Mill-Turn mode of CAMWorks For Solid Edge 2022, for Face Finish operations, if user unchecks the Undercutcheckbox option under Face Finish tab and saves the changes, then up on revisiting this tab, it is observed that the checkbox option gets rechecked.

4. CW-116932 CSR-21352 Feed Speed Even if the 'Max Feedrate' value is changed in the TechDB,it does not get updated for an operation after reselection of machine and execution of Rebuild command.

5. CW-116822 CSR-21320 UIF For Mill parts having Pattern Project operations, when the pattern type for it is set to "Radial" and Point Selection option is selected, the image displayed in Preview window is of "Spiral" output type instead of "Radial" type.

6. CW-116769 CSR-21029 Post Change the behavior of the post variable "IS_WRAPPED"so that it is not set to TRUE for Entry Drill/Hole operations generated along with Rough or Contour Mill operations for the Wrapped features.

7. CW-116765 CSR-21260 Post In Mill-Turn mode, for Wrapped features, the wrong arc angle values are getting generated for Sub Spindleoperations. This is due to incorrect computation for ARC_INC_ANGLE variable.

8. CW-116681 CSR-20765 Feed Speed In Mill mode, the Feed/Speed values for Rough Mill and Contour Mill operations are not correctly modified based on the Axial cut depth factor in the Feeds and Speeds Library

9. CW-116649 CSR-21155 Feature For the specific Mill part with irregular slot feature, the wrong largest Inscribed Circle is being used to recognize the slot feature resulting in incorrect tool selection.

10. CW-116571 CSR-21104 TechDB For the customer-specific TechDB file, in the Thread Mill user interface, the data associated with thread type "MF"is missing. When the same TechDB file is linked to the CAMWorks For Solid Edge application, the data related to MF tools is visible in the relevant user interface.

11. CW-116512 CSR-21012 Post For the specific Assembly file with 8 component parts, when post processing with the custom Post Processor, more time than standard processing time is taken. However, if the default 'M3AXIS_TUTORIAL.CTL' post processor is used, the time taken for post processing is on par.

12. CW-116507 CSR-20955 API Customer uses API to determine the location of MT files associated with user-defined tools. However, when inserting API in C# codes, desired results are not achieved.

13. CW-116471 CSR-20604 Operation For customers using APT post, a pre-Implementation that allows addition of a "PostName.ASP" (Active Smoothing Parameters) file that instructs the system to activate smoothing parameters using the ModuleWorks parameterdefaults is required for Multiaxis Operation parameters.

14. CW-116466 CSR-21019 System When the specific Mill part is opened in any CAMWorks For Solid Edge versions released after CAMWorks For Solid Edge 2020 release, if user adds a new toolpath and executes the Save command to save the changes, then an error message indicating failure to save new data getsdisplayed. User is unable to save toolpath additions.

15. CW-116442 CSR-20917 TechDB In the TechDB, for Mill "Open Profile/ Open WrappedProfile" feature, the Tool type definition for Feature Condition with ID '219' is missing.

16. CW-116369 CSR-20970 Feed Speed If the decimal symbol is changed from "." to "," (Comma) within the Regional Settings option of Windows Control Panel, then it affects the new Material Library. If a newmaterial is created in the Material Library, then thefunction of Feeds and Speeds by percentage of default material does not work. All the values are displayed as zero.

17. CW-116335 CSR-20943 Toolpath For the specific Mill parts, the Rough Mill toolpath generates extremely small arcs that cannot be posted resulting in overcutting while machining.

18. CW-116330 CSR-20929 TechDB For exporting the customized TechDB, the supported file type indicated is in CSV (*.csv) format. However, up on executing the export command, the file extension appearsas ".cwjs.csv". This file format cannot be re�imported in SOLIDWORKS CAM having standard license as the supported file type is pre-set to *.cwjs.

19. CW-116316 CSR-20918 CSR-21293 Operation For specific Turn part, on generating an operation for its Turn Drill operation, the machining length generated using expression or constant defined in the custom TechDB does not get applied to the toolpath machining depth.

20. CW-116304 CSR-20910 TechDB In Turn mode, right-clicking on any Turn feature in the Feature tree and selecting Parameters in context menu will display the Feature Parameters dialog box. Clicking on the TechDB ID for strategy selected in Strategy drop-down list launches TechDB application and displays the features and operations. However, data for the wrong TechDB ID is getting displayed.

21. CW-116254 CSR-20869 Post For the specific Mill part that uses a Corner Round tool for its Mill operation, the APT code generated using MILL Apt post does not output the radius of Corner round toolunder Cutter details.

22. CW-116203 CSR-20726 API Existing API: "CWPostOperationParam::get_PostParamValueList()" is not functioning correctly.

23. CW-116194 CSR-20825 Post When using custom Post Processor to generate posted output, the output of post variables CI, CJ, CK, MACH_CI, MACH_CJ and MACH_CK for vector contact point forMirror toolpaths is incorrect.

24. CW-116092 CSR-20741 API The API function 'GetLeadAmt' or 'GetLeadAmt2' on a 'CWLeadInOut' object "percent" returns incorrect valuefor Leadin/Leadout, even when the percentage is selected.

25. CW-116089 CSR-20810 UIF For the specific Mill part having more than hundred surface bodies, when user attempts edit its stock definition by executing the command, it takes more than 45 seconds to load the Stock Manager dialog box.

26. CW-116059 CSR-20797 Operation For any Turn part having the Rectangular Groove features on its Outer diameter that are machined from Main Spindle and Sub Spindle, if the same tool is used for machining these groove features, then the tool and holder orientation changes after generating of operations. This change to incorrect orientation results in failure to generate toolpaths.

27. CW-116046 CSR-20751 Toolpath In Mill Part and Assembly modes, when the 'Avoid'checkbox is checked to avoid fixtures and the Step through command is executed, then the Contour Mill toolpath get duplicated.

28. CW-116040 CSR-20734 Post When the specific custom Post Processor is used, the TOOL_ANGLE variable doesn't reset to 0 for non-tapered tools.

29. CW-115914 CSR-20710 System Whenever user tries to generate a 5 Axis Mill toolpath for the specific part, the user's computer crashes.

30. CW-115856 CSR-20642 UIF For Multiaxis operations, when the "New Avoid Area..." function is applied to any toolpath the operation for this doesn't get displayed in the Operation tree. This occurs as Avoid Area function is not supported for Multiaxis operations.

31. CW-115773 CSR-20602 TechDB In TechDB application, the Threading parameters needs to be updated for Tap Rolling and Tap Cutting strategies.

32. CW-115390 CSR-20451 Stock The specific STL based Stock File does not maintain C/S Associativity with the part model unless the first Bounding box option is selected from the stock type in 'Stock Manager' user interface.

33. CW-115367 CSR-20446 Stock In Milling mode, if cylindrical stock shape is selected andassociated parameters are assigned, then the cylindrical stock consequently created has incorrect dimensions as double the value of 'Diameter Offset' parameter is considered.

34. CW-115357 CSR-20438 TechDB The Feature Parameters strategy window doesn't connect to the correct strategy in the TechDB application and highlights some other Feature strategy within the list.

35. CW-115345 CSR-20407 Operation In Mill mode, for Contour Mill operations, the percentage (%) based 'Cut Amt.' parameter for Contour Mill side parameter rough passes does not work correctly. This seems to be an incorrect calculation logic issue.

36. CW-115327 CSR-20420 User Interface For Contour Mill operations, the option "Add tool radius to leadin/leadout" under NC Tab has been removed from CAMWorks For Solid Edge 2022 version onwards. However, this option is still present in the User interface of the TechDB application.

37. CW-115111 CSR-20286 VoluMill In Assembly mode, when all fixture components are marked as 'Avoid Fixture' in the Mill Part Setup, then the

2.5 Axis VoluMill toolpath does not generate correctly. The areas above the fixtures do not get machined.

38. CW-115041 CSR-20141 Setup Sheet The images for Tool Setup sheets are present in the wrong folder. Consequently, when generating a Setup Sheet, the images of the tool inserts are missing from the Setup Sheet Pages.

39. CW-114999 CW-114843 CSR-11036 Toolpath For the specific Mill part, the contour mill toolpath generates an extra plunge move at the start of the second and subsequent depths of cut.

40. CW-114517 CSR-19769 VoluMill For the specific Assembly file, the Rough Mill toolpath for the Face Feature (with Avoid Area defined using a sketch)is correctly generated when pocketing pattern is set to Zigzag. When pocketing pattern is set to VoluMill, a wrong toolpath is generated.

41. CW-114309 CSR-19620 Operation For the specific Mill-Turn part with Main and Sub Spindle Coordinate systems, the coordinates for the Sub Spindle get flipped. Consequently, the Sub Spindle operations generated have incorrect orientation.

42. CW-114279 CSR-19575 User Interface For the specific Turn part, in the CAMWorks For Solid EdgeFeature Tree, the yellow colored warning icons displayedfor the Turn Features and Turn Setups are do not get removed even after executing Rebuild.

43. CW-114272 CSR-19561 Tool When the Tool ID is changed in the Additional details (Tool/Holder) dialog box of Edit Tool Parameters, then up on saving the Tool Crib to TechDB it does not count it as an updated tool to be saved. This behavior is observed only when the other parameter "Vendor" in Additional details (Tool/Holder) dialog box is kept blank.

44. CW-113519 CSR-19361 TechDB In TechDB, for Probing operations, when a new operation is created and saved in "Default Operation Parameters"user interface and then used in the CAMWorks For Solid Edge application, Probe toolpath for that operation will not be generated.

45. CW-113481 CSR-19286 Operation For the specific assembly file, when inserting a new Contour Mill operation, if the "Copy from" another tool option is selected in Operation Parameters and the toolpath is generated, then the machining depth of the toolpath is incorrectly calculated.

46. CW-113164 CSR-19235 VoluMill For the specific Mill assembly, when applying the "Avoid Fixture" condition to the VoluMill toolpath, it fails to avoidthe designated Fixture components.

47. CW-112848 -- Setup Sheet When publishing a Setup Sheet for specific Turn part, the Turn Holder parameter for Protrusion does not get output to the Setup Sheet in XML format

48. CW-112846 CSR-18810 Operation For the specific Mill-Turn part, when Sync Manager userinterface is closed using OK or Cancel command, then up on reopening, the defined operation sequence for rear and front turrets is lost.

49. CW-112820 CSR-18866 System For the specific Mill part, when attempting to generate toolpath for the copied Drilling operation, CAMWorks For Solid Edge freezes and needs to be reloaded.

50. CW-111717 CSR-18243 API When adding Avoid area or Contain area to an operation using CAMWorks For Solid Edge API, a COM-Error is encountered.

51. CW-111574 CSR-18077 Operation For the specific Mill-Turn part, all the turn operations display error reporting that the leadin/leadout moves are gouging the part. This error is present even when the Gouge detection option is disabled.

52. CW-110716 CSR-17722 API CAMWorks For Solid Edge API: CWTpBaseFeature gives COM Exception error.

53. CW-110534 CSR-17538 API When adding the Hog nose tool using the API, the Stock material dropdown list from Cutting Parameters UI does not display all available materials.

54. CW-109894 -- User Interface When filtering tools on the Tool Crib page, the Tab key does not work as expected when shifting focus to other fields.

55. CW-109702 CSR-16630 Setup Sheet Customer has requested information associated with four variables to be made available in custom Setup Sheet.

56. CW-109524 CSR-17016 Operation For the specific assembly file, the Contain area defined for then its Pattern Project operation changes when the Mill Setup is opened and closed. The toolpath generated also reflects the changed contain area.

57. CW-109043 CSR-16798 Toolpath In the assembly mode, for the generated Contour Mill operation, the Gouge option under NC tab is checked, theRamp option under Contour tab is set to 'Cut Amount' and the Toolpath center is set to 'Without compensation'. When the toolpath is generated for this operation, it is incorrect as it starts machining from bottom of the feature.

58. CW-108504 CSR-16727 Toolpath For the specific Mill part file, the NC code for the Cutter compensation on Final Contour Mill pass are notgenerated for its Part perimeter - Open Pocket feature.

59. CW-108288 CSR-16607 Rebuild For the specific Mill part, the Rest Machining operation for Roughing passes with 0.25 Tool 4 Flat End Mill takes many minutes to execute when performing Rebuild and/orgenerating toolpath.

60. CW-108063 CSR-16499 Operation If identical tools are present in multiple tool stations of a tool crib, then for some mill parts, then while interactively inserting a new 3 Axis Mill operation with a different tool assigned, it is observed that the tool present at multiple stations gets assigned instead.

61. CW-107622 CSR-16301 Feature For the specific Mill part, the hole group and multi-stephole group features that are blind are incorrectly recognized as through features and connected to holes on the opposite face.

62. CW-107239 CSR-16139 Simulation For the specific Turn part having long cylindrical surfacewith numerous facets, the simulation performance of the toolpath for this surface is poor when the 'Show difference' option is selected.

63. CW-105917 CSR-15600 Tool In Turn mode, for the specific user defined turn insert, the displayed location of tip offset is incorrect. This affects posted NC code and must be corrected.

64. CW-105895 CSR-15583 Feature For the specific Mill part, the Curve feature definition doesn't apply or retain the correct tool side vector.Consequently, when the toolpath is generated, a gouge observed on the part.

65. CW-104435 CSR-14967 Toolpath For the specific Mill part, the toolpath for the Face Mill Operation does not get generated on second attempt afterright-clicking on the Mill Part Setup in NC Manager to execute command for toolpath generation. It also prevents Face Mill toolpath generation on a fresh part when the earlier part is still open in a separate window.

66. CW-103827 CSR-14617 VoluMill For 2.5 Axis Mill parts, the VoluMill toolpath generated for a pocket feature having defined 'Avoid Area' will not machine at the top of that Avoid area whereas toolpaths generated using any other Pocketing Pattern will always machine the at the top of Avoid area.

67. CW-102576 CSR-14041 Toolpath For the specific Mill part, the Contour Mill Rest Machining generated for its Perimeter boss feature has unwanted air cutting moves on the outer periphery corners of the perimeter boss feature.

68. CW-102424 CSR-14044 VoluMill For the specific Assembly file, the 2D VoluMill toolpathfails to maintain the First Cut Amount percentageconsidering the tool diameter at the depth parameter when the Rest Machining is set by WIP. The excessive first cut depth causes the toolpath gauge.

69. CW-101613 CSR-10459 VoluMill VoluMill toolpaths do not generate for Open Pocket Part Perimeter feature.

70. CW-100179 CSR-13189 User Interface For large and very complex part models, executing the Contain Area or Avoid Area commands takes many seconds to load and display the associated user interface. The display must happen almost instantaneously up on executing the command.

CAMWorks for Solid Edgebrings proven, state-of-the-art machining capabilities to Solid Edge users. Since it is accessible directly in the Solid Edge window, CAMWorks for Solid Edge provides a consistent user interface and eliminates time-consuming file transfers. With Geometric's patented Feature Recognition technology running in real-time to capture machined features and automatically generate or update the toolpath, manufacturing-driven design changes can be made to any CAD model using synchronous technology, a unique capability which combines the speed and flexibility of direct modeling with the precise control of dimension driven design. This dramatically streamlines what has traditionally been a time-consuming process. The solution also captures the machining strategy in a customizable database, TechDB, thus allowing efficient machining solutions to be reapplied to future designs with similar features, further enhancing productivity.CAMWorks for 2022provides advanced new features to help you take full advantage of your CNC machines

CAMWorks 2022 Tips & Tricks

GeometricPLM by HCL Technologiesa specialist in the domain of engineering solutions, services and technologies. Its portfolio of Global Engineering services, Product Lifecycle Management (PLM) solutions, Embedded System solutions, and Digital Technology solutions enables companies to formulate, implement, and execute global engineering and manufacturing strategies aimed at achieving greater efficiencies in the product realization lifecycle.

On April 1st 2016, Geometric got into an agreement with HCL Technologies to transfer of its business to HCL Tech by way of demerger, except for its 58% share in the joint venture with Dassault Systèmes (3DS) (3DPLM Software Solutions Limited (3DPLM)). The transition has become effective on March 2nd 2017, after seeking all statutory approvals.

Buy Premium From My Links To Get Resumable Support,Max Speed & Support Me

Links are Interchangeable - Single Extraction

Comments