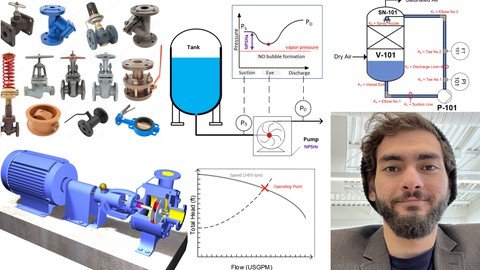

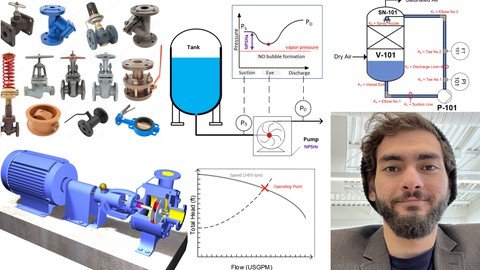

Pump Sizing & Modeling Piping Systems For Liquids

Author: crackserialsoftware on 25-05-2023, 23:25, Views: 99

Free Download Pump Sizing & Modeling Piping Systems For Liquids

Free Download Pump Sizing & Modeling Piping Systems For LiquidsPublished 5/2023

MP4 | Video: h264, 1280x720 | Audio: AAC, 44.1 KHz

Language: English | Size: 5.94 GB | Duration: 6h 21m

Learn to size pumps and model piping systems & valves, calculate pressure drop through fittings, valves and components

What you'll learn

Modeling of piping systems, components, fittings and valves for incompressible fluid.

Understand the Darcy equation, resistance coefficient (K), friction factor (f), flow coefficient (Cv), and orifice design.

Identify and understand the basic components of a pump and calculate pumps Hydraulic Horsepower , Brake Horsepower , Pump Efficiency, Motor Power & Motor Eff.

Understand pump curves for different impeller speeds (or diameters), pump efficiency curves, pump NPSHr curves and Power consumption curves.

Develop a roadmap for proper selection of pumps via excel macros and model resistance in series for a piping system.

Understand inherent valve curves, different types of control valves, valve authority, and size valves appropriately for a given system.

Requirements

While having prior engineering or field knowledge is desirable, it is not necessary for this course. The course is designed to explain all concepts in a clear and understandable language, allowing students to develop their knowledge from the basics.

No prior Excel macros knowledge required. Everything will be taught in this course.

Description

Chapter 1: Introduction1. Differentiate between incompressible and compressible fluids using the continuity equation.2. Define and understand general concepts in fluid dynamics, such as viscosity (dynamic and kinematic), Reynolds number (laminar and turbulent flow), and volumetric flow rate.Chapter 2: Energy Balance3. Derive and apply the Bernoulli equation to develop an energy balance for sizing pumps.4. Understand the pump equation and its relation to the Bernoulli equation.5. Apply the pump equation to an illustrative example.6. Create system curves for a piping system.Chapter 3: Friction Headloss7. Understand hydraulic resistances in pipes.8. Define the Darcy equation and its application in calculating frictional headloss.9. Define the resistance coefficient (K) and calculate it using different methods.10. Define the friction factor (f) and calculate it using numerical methods via the Poiseuille equation, Colebrook equation, Swamee Jain equation, or the Moody chart.11. Understand the effect of pipe age on friction factor.12. Define flow coefficient (Cv) and its application in calculating pressure drop.13. Adjust Cv for liquids with different viscosities.14. Find the capacity flow rate at different pressure drops for a given Cv.15. Convert flow coefficient (Cv) to a resistant coefficient (K).16. Understand the use of orifice plates and use the orifice design equation to size orifice plates.17. Apply the orifice design equation in an illustrative example.Chapter 4: Pumps18. Identify and understand the basic components of a pump.19. Calculate pumps Hydraulic Horsepower (HHP), Brake Horsepower (BHP), Pump Efficiency, Motor Power (MP), and Motor Efficiency through an example.20. Understand pump curves (head vs flow rate) for different impeller speeds (or diameters).21. Understand pump efficiency curves.22. Understand Pumps Net Positive Suction Head Required (NPSHr) Curve.23. Understand Pump Power Consumption Curve.Chapter 5: System Modeling and Pump Sizing Roadmap24. Model resistance in series for a piping system.25. Develop a roadmap for proper selection of pumps.Chapter 6: Case Study 126. Apply the pump sizing roadmap using Macros in Excel to select an appropriate pump for a real-world case study.Chapter 7: Control Valves27. Identify different types of control valves and their applications.28. Understand the inherent valve curve and its relation to flow rate and pressure drop.29. Define valve authority and its significance in valve selection.30. Size valves appropriately for a given system.

Overview

Section 1: Introduction

Lecture 1 About This Course

Lecture 2 Teaching Style

Lecture 3 Incompressible vs Compressible Fluids

Lecture 4 General Definitions: Viscosity (Dynamic vs Kinematic)

Lecture 5 General Definition: Reynolds Number (Laminar vs Turbulent Flow)

Lecture 6 General Definition: Flowrate

Section 2: Energy Balance

Lecture 7 Bernoulli's Principle: Fluid Total Energy

Lecture 8 Bernoulli's Principle: Energy Terms &Units

Lecture 9 Pipe Energy Balance Derivation Part 1

Lecture 10 Pipe Energy Balance Derivation Part 2

Lecture 11 Pipe Energy Balance Units

Lecture 12 Pump Energy Balance

Lecture 13 Example (Problem Statement)

Lecture 14 Example (Solution Part 1)

Lecture 15 Example (Solution Part 2)

Lecture 16 Example (Solution Part 3) - System Curves

Section 3: Friction Head Loss

Lecture 17 Darcy Equation, Resistance Coefficient

Lecture 18 Resistance Coefficient Examples

Lecture 19 Friction Factor

Lecture 20 Moody Chart

Lecture 21 Effect of Pipe Age on Friction Factor

Lecture 22 Flow Coefficient Cv

Lecture 23 Flow Coefficient Cv - viscosity and specific gravity correction

Lecture 24 Flow Coefficient Cv - capacity flowrate at different pressure drops

Lecture 25 Flow Coefficient Cv - Conversion to Resistance Coefficient K

Lecture 26 Orirfice Plate

Lecture 27 Orifice Plate Example

Section 4: Pumps

Lecture 28 Pump Intro

Lecture 29 Pump Parts

Lecture 30 Pump Power Losses

Lecture 31 Pump HHP, BHP,MP Efficiency

Lecture 32 Pump HHP, BHP,MP Efficiency Example

Lecture 33 Pump Curve

Lecture 34 Pump Performance Curves

Lecture 35 Pump Performance Curves Example

Lecture 36 Pump VFDs

Lecture 37 NPSH

Lecture 38 Affinity Laws

Section 5: System Modeling and Pump Sizing Roadmap

Lecture 39 Resistances in Series

Lecture 40 Pump Sizing Road Map

Section 6: Case Study I

Lecture 41 Case Study 1 - Problem Statement

Lecture 42 Case Study 1 - Solution Road Map

Lecture 43 Case Study 1 - Solution (Part 1)

Lecture 44 Case Study 1 - Solution (Part 2)

Lecture 45 Case Study 1 - Solution (Part 3)

Lecture 46 Case Study 1 - Solution (Part 4)

Lecture 47 Case Study 1 - Solution (Part 5)

Lecture 48 Case Study 1 - Solution (Part 6)

Lecture 49 Case Study 1 - Solution (Part 7)

Lecture 50 Case Study 1 - Solution (Part 8)

Section 7: Control Valves

Lecture 51 Valve Basic Parts

Lecture 52 Valve Classification

Lecture 53 Control Valves

Lecture 54 Inherit Valve Curve

Lecture 55 Inherit Valve Curve Example

Lecture 56 Valve Authority

Engineers In-Training, Recent College graduates, Engineering Students,Chemical, Process, Petroleum Engineers,Piping, Plant Engineers,Mechanical Engineers,Maintenance Technicians,Plant Operators,Safety Engineers

https://www.udemy.com/course/pump-sizing-modeling-piping-systems-for-liquids/

Buy Premium From My Links To Get Resumable Support,Max Speed & Support Me

Links are Interchangeable - Single Extraction

Comments